Precision Packaging for Timepieces

When it comes to watch packaging, brands require more than just a functional case – they need a solution that reflects their craftsmanship, reinforces brand identity, and offers a seamless manufacturing process. Custom luxury wooden watch boxes provide a durable and refined presentation that enhances the value of the timepiece inside. But beyond aesthetics, the process of designing and manufacturing these boxes requires careful planning, material selection, and precision engineering.

Concept Development & Design

Defining the Brand Identity

The first step in creating a custom wooden watch box is defining the design requirements. Every watch brand has a unique identity, and packaging should reflect that identity with a well-thought-out concept. The dimensions of the box must be carefully planned to ensure the watch is displayed in the best possible way while being securely housed.

Minimalist vs. Collector’s Packaging

The interior design is equally important – some brands prefer a minimalist presentation, with a single watch displayed on a plush cushion, while others opt for multi-watch storage options that cater to collectors.

High-end watch brands such as Rolex and Omega use packaging that reflects their brand heritage. Rolex, for example, incorporates classic green lacquered wooden boxes lined with luxurious suede, ensuring a prestigious unboxing experience that enhances the product’s exclusivity. Meanwhile, more modern brands like TAG Heuer experiment with sleek wooden cases with carbon fibre inlays to align with their contemporary, performance-driven branding.

Selecting the Right Wood & Finishes

Choosing the Right Type of Wood

The choice of wood is essential in determining both the aesthetics and longevity of a custom watch box. Hardwoods such as walnut, mahogany, and oak are popular due to their durability and rich grain patterns, which exude elegance. Lighter woods like maple or ash offer a more modern appeal and can be easily stained or painted to match brand aesthetics.

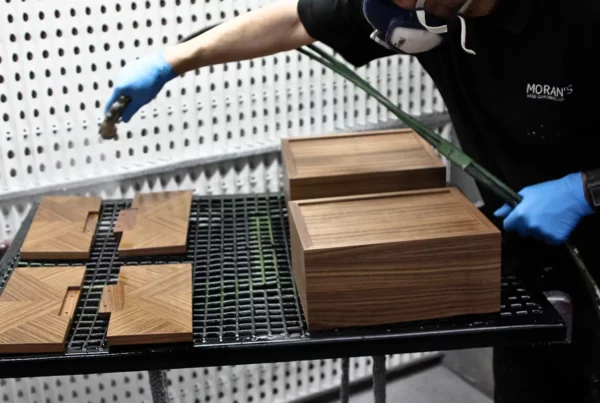

Wood Finishes and Their Impact

Wood finishes can significantly impact the final appearance. Matte, gloss, or textured coatings help to bring out the natural grain of the wood or provide a sleek, modern look. Some brands use hand-polished finishes to achieve a mirror-like sheen, while others prefer a rustic, untreated wood appearance for a more natural aesthetic. Patek Philippe, for instance, uses highly lacquered wooden boxes for their timepieces, reinforcing their image of classic sophistication.

Precision Engineering & Construction

Manufacturing with Accuracy

Once the design is finalised, the manufacturing process begins. Precision is key, as watch boxes need to be constructed to exact specifications to ensure seamless fit and function. Advanced CNC machining is used to cut each component to precise measurements, allowing for intricate detailing and perfect alignment.

Hardware and Functional Design

Traditional wood joinery techniques, such as dovetail or tongue-and-groove joints, are often employed to create robust, long-lasting structures. For luxury brands, hardware selection is another critical factor. Soft-close hinges, hidden magnetic closures, and custom lock mechanisms add to the experience of opening a high-end timepiece. The smooth movement of the hinges and the satisfying click of a well-fitted closure contribute to the tactile experience, reinforcing the premium nature of the watch inside.

Interior Customisation & Branding

Enhancing the Inside of the Box

The inside of the watch box plays just as important a role as the exterior. A finely crafted wooden case must complement the watch, ensuring both protection and presentation. Luxury brands often use suede, velvet, or leather linings, providing a soft, cushion-like surface that cradles the watch securely. High-end examples, such as Breguet’s wooden watch boxes, showcase polished wood exteriors with rich grain patterns and cream suede interiors that provide a soft, protective cushion for the timepiece. The gold-tone hardware and precision craftsmanship enhance the presentation, reinforcing Breguet’s commitment to elegance and sophistication.

Brand Identity Through Packaging

Branding elements are another opportunity for differentiation. Some manufacturers incorporate engraved logos, embossed lettering, or gold-plated plaques inside the lid to reinforce brand identity. Custom inserts and compartments may also be added, particularly for brands that offer multiple watch storage options, catering to collectors who prefer to house their timepieces in a single, elegant case.

Quality Control & Finishing Touches

Ensuring Durability and Perfection

Before final production, each wooden box undergoes meticulous quality control. A well-made watch box should feel solid and refined, with smooth finishes and perfectly aligned elements. Durability tests ensure the box can protect the watch from dust, moisture, and impact, maintaining the integrity of the timepiece over time. Many high-end brands also conduct drop tests and climate testing, ensuring the wooden packaging can withstand environmental changes.

Final Customisation and Presentation

Once quality checks are complete, the final finishing touches are applied. Some brands prefer a subtle branding approach, with laser-etched logos, while others use ornate inlays or metal plaques to highlight their exclusivity. Companies like Audemars Piguet have embraced minimalist branding, with understated logos embossed into the wood, ensuring the focus remains on the watch itself.

Why Work with a Specialist Wooden Box Manufacturer?

For watch brands, working with an experienced manufacturer ensures a seamless transition from concept to production. At Moran’s Wood Components, we specialise in crafting bespoke wooden watch boxes tailored to the specific needs of luxury and boutique watchmakers.

The Moran’s Wood Components Advantage

Our process is built on craftsmanship and innovation, offering:

- Tailored design solutions that align with brand aesthetics and functional needs.

- Sustainable wood sourcing, ensuring ethical and responsible materials are used.

- Advanced manufacturing techniques, combining traditional craftsmanship with modern precision engineering.

If your brand is looking for a trusted partner to create high-quality wooden watch boxes, get in touch with us today. Our expertise in bespoke wooden packaging ensures that every box is designed with precision, sophistication, and functionality in mind.